Magnet Cup With Block Shape Steel Enclosure (ML)

Magnet Cup(ML series)

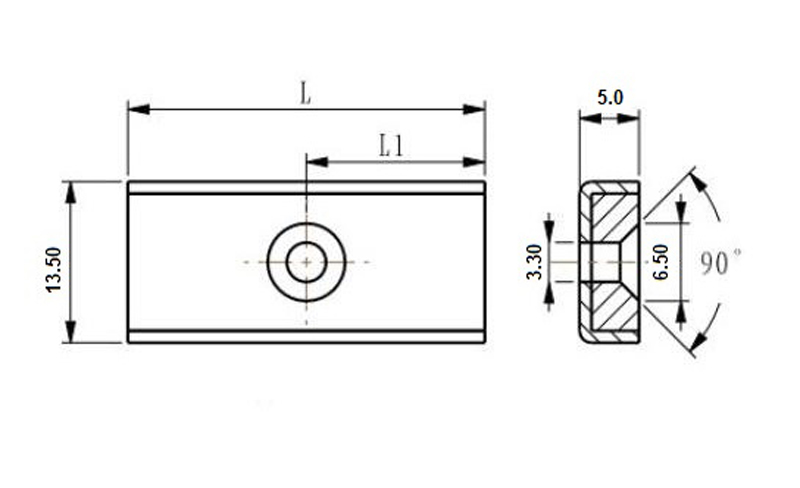

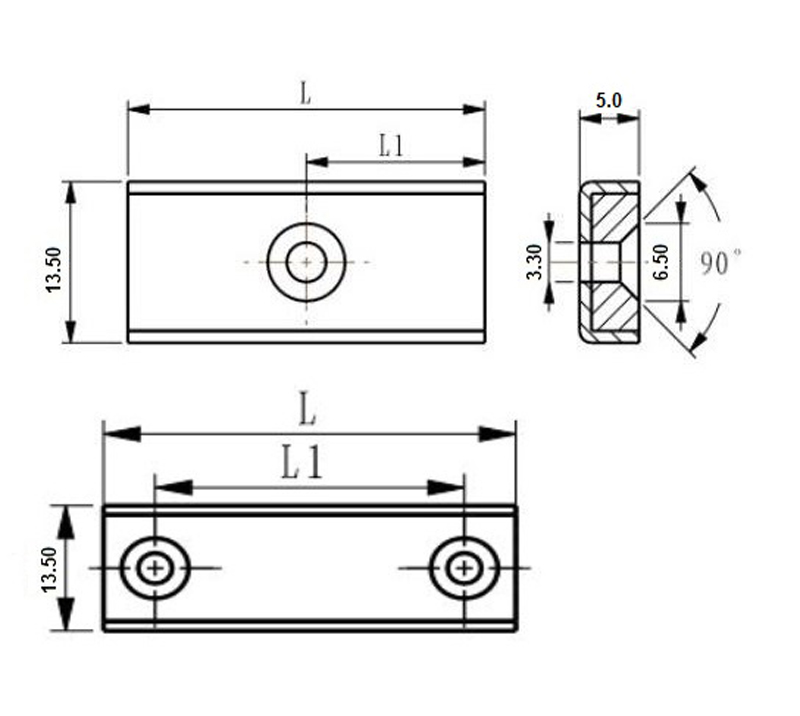

| Item | BLK Size | L size | Holes distance | Hole size | Countersink hole size |

| ML10 | 10x13.5x5 (single hole) | 10 | 5 | Φ3.3 | Φ6.5 |

| ML15 | 15x13.5x5 (single hole) | 15 | 7.5 | Φ3.3 | Φ6.5 |

| ML20 | 20x13.5x5 (single hole) | 20 | 10 | Φ3.3 | Φ6.5 |

| ML30 | 30x13.5x5 (single hole) | 30 | 15 | Φ3.3 | Φ6.5 |

| ML40 | 40x13.5x5 (double holes) | 40 | 30 | Φ3.3 | Φ6.5 |

| ML50 | 50x13.5x5 (double holes) | 50 | 40 | Φ3.3 | Φ6.5 |

| ML60 | 60x13.5x5 (double holes) | 60 | 50 | Φ3.3 | Φ6.5 |

| ML80 | 80x13.5x5 (double holes) | 80 | 70 | Φ3.3 | Φ6.5 |

| ML100 | 100x13.5x5 (double holes) | 100 | 90 | Φ3.3 | Φ6.5 |

| ML120 | 120x13.5x5 (double holes) | 120 | 110 | Φ3.3 | Φ6.5 |

Product Features

1. Neodymium block magnet with steel enclosure, attraction power are customized according to customers applications. It is made of rare earth magnets, more safe and strong with steel enclosure protections!

2. Neodymium block magnet with steel enclosure have wide range of applications including daily life use, heavy duty industrial use, construction use, civil engineering use, mining application etc.

3. Neodymium block magnet with steel enclosure dimensions and strength can be customized. Colors can be at your preference. Such as black, white, green, silver, gold, red, etc. MQO may be applied for special colors.

4. Neodymium block magnet with steel enclosure normal working temperatures are up to 80℃ degree, high temperature are up to 220℃ can be customized.

5. We also provide other components for neodymium block magnet with steel enclosure. Such as screws and steel plates, etc. they can be purchased separately.

6. We provide stamping and rubber compression and plastic injection molding services, mostly related to magnets and magnet assemblies.

7. More stronger neodymium block magnet with steel enclosuret are available. Max. we could achieve 54 MGOe in BH. Grade N54.

Magnetic production tolerances & other controlled procedures:

1. Tolerances: normal print tolerances ±0.12mm, Magnetic production controlled tolerance: ±0.05mm; Tight tolerance ±0.02mm achievable. Best tolerance ±0.015mm (achievable by using Magnetic optical inspection machine).

New optical inspection machine could be customized besides our existing ones.

2. Magnetizing: magnets are magnetized according to print requirements. pay attention to N, S pole. Multi-poles magnetizing fixtures are available. Special magnetizing coil can be customized.

3. Finished products sampling test: magnetic properties test and measurements test. pulling force test. file test data. test report (such as BH curve) can be achieved according to customer requirements.

4. Packing: safety packing. safety packing by ocean or air shielding packing by air. Most of the customers require air safety packing as most of customers require air shipments.

5. Shipments: we are shipping out air shipments frequently. Magnets shipments could be arranged and can be shipped with door too door service. We provide both DDU and DDP service.

6. Feedback: collecting feedback from customers and check possible issues, file feedback and take correcting measures.